A CAD Model of a Boeing 747-8

This was the first project I did in Solidworks. I did this with a team, but I was responsible for the hull, wings, and the tail. I also did the fluid simulation on the wing. This was a great learning experience for me as I was able to learn a lot about CAD and fluid simulations. One of the most challenging aspects of this project was the curvature of the hull. I had to learn how to use the loft feature in Solidworks to create the hull and used guide curves to control the shape.

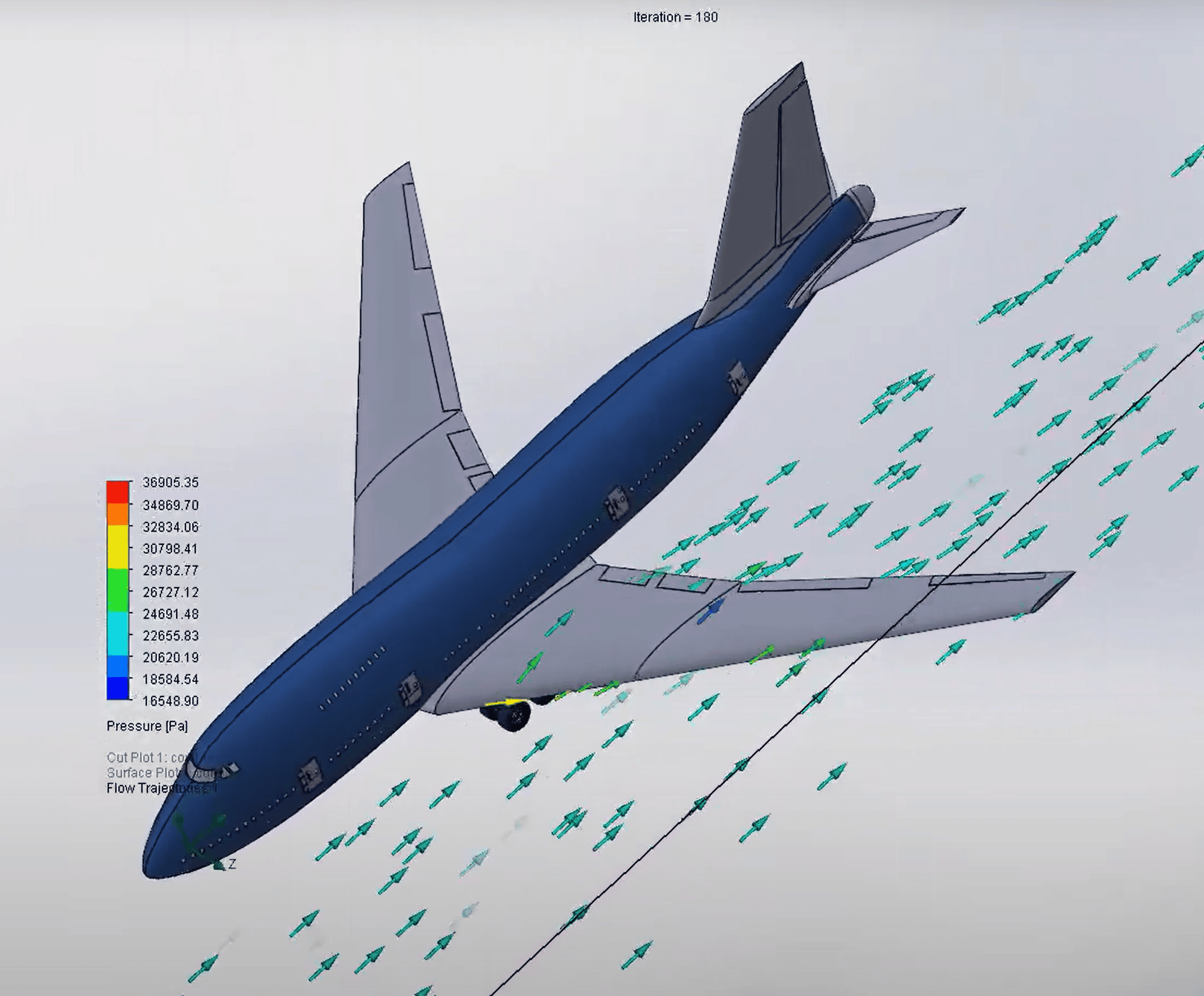

The Fluid Simulation

When I had pieced together the 747, I wanted to take things a step further and run a fluid simulation on the wing. I was able to do this using Solidworks flow simulation. This was really cool as I was able to see the airflow over the wing and see how the air would move over the wing. This was a great learning experience for me as I was able to learn a lot about fluid simulations in Solidworks. I’m pretty sure this will come in handy perhaps in the Marine Design Club where we are looking at designing a hydrodynamic hull for our submarine.

Blender and Rendering

For the final presentation, I used Blender to render the 747. While Solidworks is great for CAD, it’s not the best for rendering. I was able to export the 747 as an .obj file and import it into Blender. I then used Blender to add materials and lighting to the 747. Now whenever I need to render a CAD model, I always use Blender.

Software Utilized